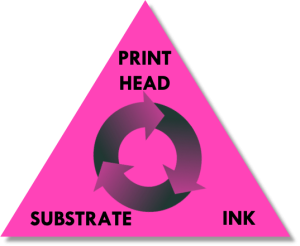

The golden triangle, where all the ‘magic’ happens

Almost every project starts with the question; “Can you print on this substrate?” where at the same time printed samples are handed over as reference.

Many companies are migrating their applications from other technologies – like litho, offset, flexo or maybe even digital toner – to digital inkjet. The output of these technologies come with a different look and feel, and will also be the case towards inkjet printing. And to make the challenge even more complex, in some cases a set of pantone colors must be achieved as well even when they are outside the color gamut of CMYK. This means that additional colors and primers are needed in cases where the substrate is leading. With the substrate is starting point we show you the consequences within the ‘golden triangle’.

The golden triangle

The 'golden triangle', the chemistry between the printhead, the ink and media.

There are three components that determine which print image quality and color gamut can ultimately be achieved. These components are printhead, ink and substrate, and form the golden triangle. Looking forward in the future of inkjet, next to ink primer and coatings will be added and will be changed in ‘fluid’ in the ‘golden triangle’.

So, where to start?

In many projects – where the application is converted from analogue to digital – we see that customers can be very persisting in keeping the substrate as it is. They know what they have and how it can be handled in the production chain.

The influence of the substrate is underestimated, the general assumption is that there always be an ink that ‘works’. In almost every case the answer will be that we need to perform test. And, be aware that the choice of the existing substrate has a long history before the final results was as it is, and also then to find a matching ink and substrate was an ongoing battle.

Why? The substrate properties like ink wetting, adhesion, absorption and drying have a huge effect on the behavior of the ink on the substrate, and ultimately on the image quality and color gamut what can be achieved.

So, the substrate cannot stay untouched?

Of course, the suggested substrates can be used, as long everybody understands that the substrate is one of the major parameters. So, if the substrate can’t be changed or optimized the ink set needs to be improved and most likely a primer is needed to reduce the influence, or try to eliminate the influence of the substrate.

A primer can be applied the analogue way with a flexo unit, or the digital way with printheads and a ‘jettable’ primer.

The next important aspect to investigate are the application parameters. These can also have an effect on the printhead and ink choice. Herewith you can think of:

- resolution;

- target printing speed;

- cost per print;

- required ink set;

- specific regulations and legislations;

- integration;

If you have identified these criteria, you can start to find the right ink set and printhead.

Ink type

With the wide variety of inkjet applications, there are many ink types available. Now inkjet is touching more and more different market segments, new inks become available almost every day. Ink comes in base forms like aqueous, UV curable, soft solvent, etc.

Some applications may require special type inks like magnetic (MICR), fluorescent, security (covert), edible and food safe inks, or inks that comply to special regulations of legislations.

After you have made your shortlist of possible ink sets, you need to check the specifications to see if these are compliant to printheads. These specifications are related to viscosity, surface tension, particle size and pH value etc. But the ink-set interaction between the substrate and/or primer needs to be tested and approved to see if the demands still can be achieved.

Printhead

With the shortlist of possible inks, the next thing is to select the right printhead that matches the ink, but also your application parameters. In most cases, your options are limited and you have to compromise.

Specifications upon you can select your printhead are; native resolution, printing speed, ink compliancy, drop size, ink lay down, ink recirculation, life expectancy, etc. The problem is still how reliable this combination is, and what will be the up-time of the system etc. Examples of such choices are; book printing benefits from a high native resolution for a really good edge sharpness of the text, and good readability. But for challenging inks – like white or varnish – you need a printhead, combined with a higher lay down and where the resolution is less important. But at the same time the functionality per printhead manufacture is different as it can be possible that you need two, or even more different printheads with different specifications, or even from different manufactures.

Finding the balance

To match your application requirements and reach the required image quality, it is just find the right balance. Every aspect in the golden triangle are evenly important, and when understanding the limitations of each aspect it will open a world of possibilities. If you have an application you want some advice on, just let us know. In our 25 years of inkjet experience and working with a wide variety of customers around the globe, we have the technology and the knowledge to assist. We working daily on finding the right balance by improving up-time by reliability. Your challenge is our passion

Arwin van Oostveen

International Sales Director

Mobile: +31 (0)6 21 33 14 93

Office: +31 (0)341 43 70 03

Email: arwin@djm.nl

LinkedIn: DJM

LinkedIn: Arwin van Oostveen