- Homepage

- >

- 'White Paper Factory' processing for direct mail service providers

'White Paper Factory' processing for direct mail service providers

Kern AG and DJM are working together on a 'White Paper Factory' solution for direct mail service providers

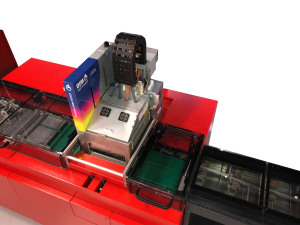

Kern Print@Exit module with DJM C500

In order to carry out the customer communication as optimally as possible, many direct mail service providers have implemented the production according to the 'white paper factory' principle.

According to this principle, blank paper is used. At the moment, the majority of letters and leaflets are already digitally printed in full-color, however, for inserting preprinted envelopes are still used, till now.

With Kerns’ Print@Exit module and DJM's fully integrated C500 full color print module, customers can implement full ’white paper factory’ processing, and benefit from many advantages.

Benefits of the ’white paper factory’ processing

Shorter time to market

Directly after the mailing has been designed, the production can be started, enabling to reach the end customers doorstep in a very short time.

Improved conversation rates

The first thing that stands out to people is the envelope. Adding 'personal messaging' on the envelope improves the impact of the mailing and contributes to a higher response and conversion.

Stock reduction

Stock reduction

By printing logo’s, address information and messages on the envelope, there is no need to have customer envelopes on stock. Only blank envelopes need to be on stock.

Uptime maximization

Different jobs can be batched together and produced one after another without stopping the system. This improves the system up-time and throughput.

Optimized envelop logistic

Less inventory costs by reducing the variety of envelopes to a blank, less is being kept in stock. There is less handling and administration in relation to inventory booking and de-stocking. In addition, risk of obsolete stock – and therefore costs – is reduced to zero.

For printing envelopes Kern implements the DJM C500 in the Print@Exit conveyor.

In connection with a Kern inserting system the conveyor is dynamically adjusting the height of the printhead, depending on the envelope thickness. This is creating a flexible solution.

The DJM C500 print module is controlled by the DJM Kameleon software, and is fully integrated into Kerns’ mailFactory software.

Benefits of the DJM C500

Automated printhead servicing

The DJM C500 is equipped with a comprehensive servicing station: the printhead capping, cleaning and wiping, ensuring maximum operator ease and up-time.

High print image quality

The DJM C500 print module has a high resolution that, combined with the small drop sizes, results in a high print image quality.

Maximum productivity

The operator doesn’t need specific inkjet knowledge to operate the system. The ink supply system is equipped with a double cartridge system, so cartridges can be changed while running and will not lead to machine downtime.

Ease of use

The DJM C500 print module is easy to use. Replacing ink cartridges, cleaners and printhead can be done by the operator and without any tools.